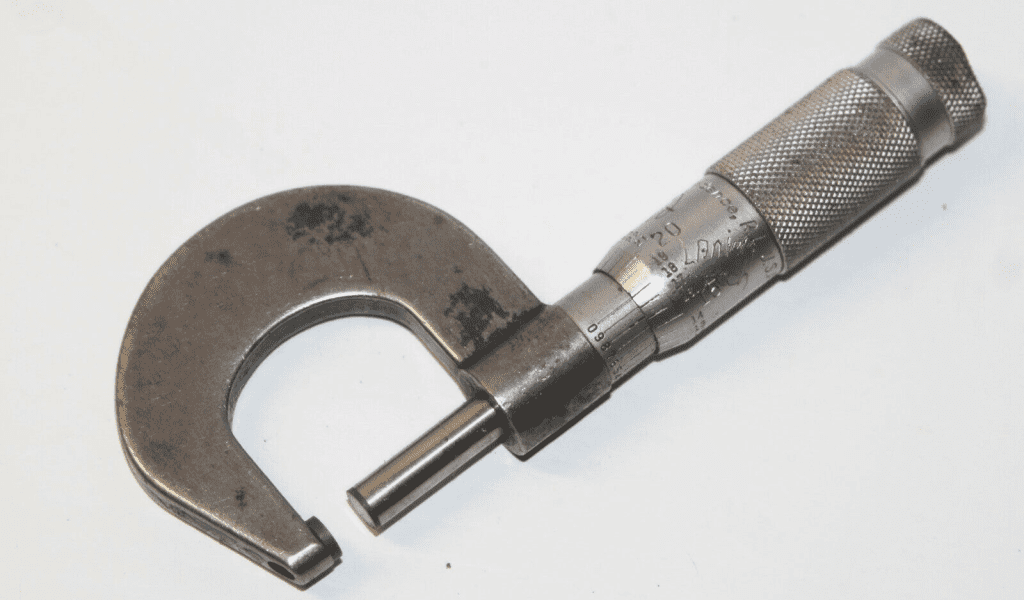

An essential device employed in a specialized area, greatly valued by those who depended on it.

The micrometer, also referred to as a micrometer screw gauge, is one of the most crucial tools in the field of precision measurement. Its development in the early 19th century marked a significant milestone in engineering and manufacturing. Invented by Frenchman Jean Laurent Rixens in 1829, this tool revolutionized how small dimensions were measured, offering a level of accuracy that was previously unattainable. Over time, the micrometer has evolved, but its fundamental role in advancing technology remains unchanged. This article delves into the history, usage, and enduring legacy of the vintage micrometer machinist tool.

The Origins of the Micrometer: A Revolutionary Invention

The micrometer has its roots in the early 19th century when accurate measurement tools were in high demand, particularly in the emerging industrial sectors. In 1829, French inventor Jean Laurent Rixens patented the first micrometer screw gauge, a groundbreaking tool that enabled machinists to measure small dimensions with precision. At the time, existing measurement devices lacked the accuracy needed for fine engineering work, and Rixens’ invention filled this gap.

Initially, the micrometer was embraced by machinists, engineers, and toolmakers who required exact measurements for quality control in manufacturing. The tool’s design allowed for extremely fine adjustments, making it indispensable in mechanical engineering, where even the smallest measurement discrepancies could lead to functional failures in machinery.

The Evolution of the Micrometer: From Basic Design to Advanced Functionality

While the basic principle of the micrometer remained unchanged—using a screw mechanism to measure small distances—the tool underwent significant improvements over the years. The introduction of the vernier scale allowed users to achieve even greater accuracy, measuring increments down to millionths of a meter or thousandths of an inch. Additionally, advancements in materials, such as the use of hardened steel, improved the micrometer’s durability and longevity.

These enhancements made the micrometer an even more reliable tool for professionals working in fields such as aerospace, automotive manufacturing, and precision engineering. Its use in measuring the thickness of materials, the diameter of components, and the distance between surfaces contributed to higher levels of quality control, setting new standards for precision.

How a Micrometer Works: The Screw Mechanism Explained

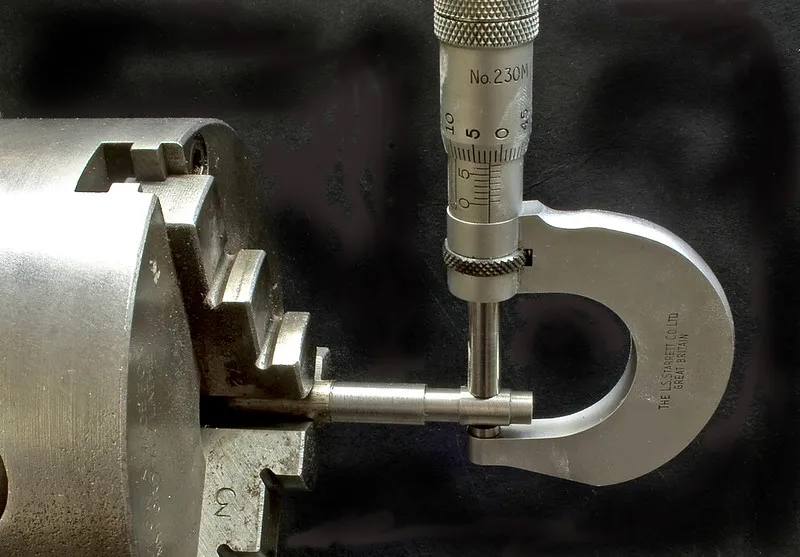

At its core, the micrometer operates on the principle of a calibrated screw mechanism. This system allows for fine adjustments, providing highly accurate measurements. A typical micrometer consists of three main components: the calibrated screw, the movable spindle, and the anvil.

To use the tool, the object to be measured is placed between the anvil and the spindle. By turning the calibrated screw, the spindle moves closer to or further from the anvil, applying pressure to the object. Once the object is secure between these two points, the user can read the measurement from the tool’s scale.

Micrometers are available in different types, each suited for specific tasks. For instance, an outside micrometer measures the thickness or diameter of an object, while an inside micrometer measures the internal dimensions of an opening, such as a hole. Depth micrometers, on the other hand, measure the depth of holes, grooves, or slots.

The Vital Role of Micrometers in Industry

The precision offered by micrometers is vital in numerous industries, including aerospace, automotive, and manufacturing. For example, in the aerospace industry, components must meet exacting standards to ensure the safety and performance of aircraft. Even the slightest variation in size can lead to mechanical failure. Micrometers are essential tools for ensuring these components meet the necessary tolerances.

In automotive manufacturing, micrometers are used to measure engine parts and ensure they fit together perfectly. This level of precision is crucial to maintaining the efficiency and safety of vehicles. Without the accuracy provided by micrometers, many modern manufacturing processes would be impossible to execute with the required level of detail.

The Transition to Digital and Electronic Micrometers

As technology advanced, so did the micrometer. In recent years, digital and electronic versions have emerged, offering even greater ease of use and accuracy. These modern micrometers feature digital readouts, eliminating the need for users to manually interpret the scale, thereby reducing the possibility of human error.

Digital micrometers are equipped with features such as data output options, which allow users to store and analyze measurement data on computers or other devices. These innovations have made micrometers even more indispensable in today’s precision-driven industries. Despite these advancements, the traditional vintage micrometer remains highly valued for its craftsmanship and historical significance.

The Legacy of the Vintage Micrometer: A Symbol of Precision Engineering

The legacy of the vintage micrometer is deeply intertwined with the evolution of precision measurement. Before the development of digital tools, micrometers were the backbone of quality control and mechanical precision in industries worldwide. The ability to measure down to the smallest increments allowed engineers and machinists to achieve tolerances that were previously unattainable, driving technological progress in fields ranging from industrial manufacturing to scientific research.

Today, vintage micrometers are often collected and displayed as symbols of engineering excellence. They represent an era when the accuracy of a tool was a reflection of the skill and dedication of its user. Collectors and enthusiasts prize these instruments for their intricate design, durability, and the critical role they played in the development of modern engineering practices.

Museums and collectors alike showcase these tools as a testament to the ingenuity of early mechanical engineering. The fact that vintage micrometers are still used in some workshops today speaks to their timeless design and the lasting impact they have had on the world of precision measurement.

Conclusion: The Enduring Importance of the Micrometer

The micrometer, a tool born from the necessity of precision, has left an indelible mark on the world of engineering and manufacturing. From its humble beginnings as Jean Laurent Rixens’ invention to the advanced digital models of today, the micrometer continues to play a vital role in ensuring accuracy in critical industries. Its legacy as a symbol of precision and craftsmanship is one that endures, with vintage micrometers still celebrated for their historical importance.

In the world of precision measurement, the micrometer stands as a tool that has shaped industries and pushed the boundaries of what is possible. Its story is one of innovation, craftsmanship, and a commitment to excellence—a legacy that will undoubtedly continue to inspire future generations of engineers and machinists.