In the world of precision engineering, attention to detail is everything. Among the many tools that engineers and machinists rely on, one stands out for its simplicity and effectiveness—the thread pitch gauge. This seemingly humble tool plays a crucial role in ensuring that threaded components fit together perfectly, whether they’re part of delicate instruments or massive industrial machinery.

Let’s dive into the fascinating world of the thread pitch gauge, exploring its importance, uses, and the essential role it plays in maintaining quality and precision across countless industries.

What Is a Thread Pitch Gauge?

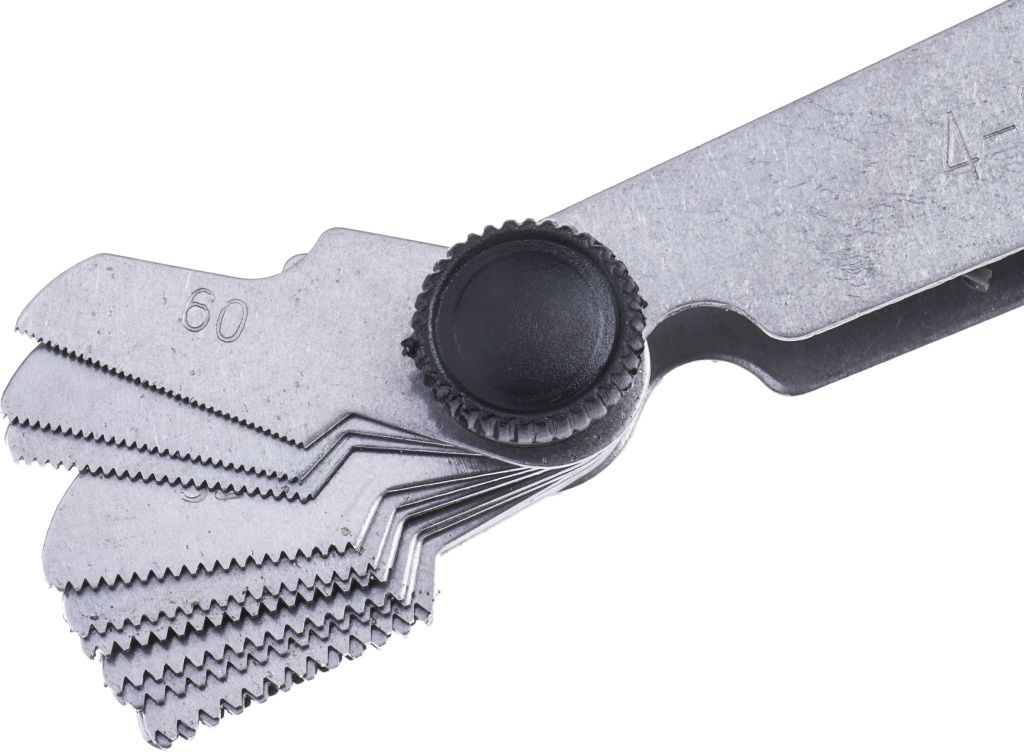

A thread pitch gauge is a compact tool designed to measure the pitch, or the distance between threads, of screws, bolts, and other threaded components. Typically made of thin metal or plastic, the gauge consists of several plates or blades, each marked with different thread pitches. By matching the teeth of the gauge to the threads on a part, engineers can quickly determine the exact pitch, ensuring compatibility and alignment with other components.

While it might not seem like much, this small tool is a linchpin in quality control. The thread pitch gauge ensures that every threaded connection meets exact specifications, preventing assembly issues and maintaining the integrity of entire systems.

The Critical Importance of Thread Pitch in Engineering

Thread pitch refers to the distance between adjacent threads on a screw or bolt, and this measurement is critical in determining how components fit together. Even the smallest discrepancy in thread pitch can lead to serious issues, including improper alignment, loose connections, or compromised structural integrity.

Think of the thread pitch gauge as the guardian of precision. By providing an accurate measurement, it helps engineers avoid these pitfalls, ensuring that each component mates seamlessly with its counterpart. Whether in automotive manufacturing, aerospace, or electronics, the thread pitch gauge prevents costly mistakes and enhances the overall reliability of the final product.

Types of Thread Pitch Gauges for Different Needs

One of the reasons the thread pitch gauge is so widely used is its versatility. There are various types of thread pitch gauges available, each suited for different thread profiles. Here are some common types:

- Metric Thread Pitch Gauges: Designed for measuring metric threads, these gauges are often used in countries that follow the metric system.

- Imperial Thread Pitch Gauges: These gauges measure threads based on the imperial system, typically used in the United States and other countries with inch-based measurements.

- Tapered Thread Gauges: Tapered threads, often used in pipe fittings, require specialized gauges for accurate measurement.

- Unified Thread Standard (UTS) Gauges: Common in North America, UTS gauges measure thread pitch according to standardized thread sizes.

Each type of gauge is designed to fit the specific characteristics of the threads it measures, allowing engineers to ensure accuracy regardless of the component’s intended application.

How to Use a Thread Pitch Gauge Effectively

Using a thread pitch gauge is straightforward, but precision is key. Here’s a step-by-step guide to using the gauge effectively:

- Select the Right Blade: Thread pitch gauges come with several blades or plates, each labeled with a different pitch size. Select the blade that you think matches the component’s threads.

- Align the Gauge with the Threads: Gently press the selected blade against the threads of the bolt or screw. If the blade fits snugly with no gaps, you’ve found the correct pitch.

- Check for Compatibility: Once you’ve identified the pitch, you can compare it with corresponding components, like nuts or tapped holes, to ensure a perfect fit.

By following these simple steps, engineers and machinists can quickly verify thread specifications, minimizing the risk of assembly errors and ensuring that components are ready for installation.

Applications of the Thread Pitch Gauge in Industry

The thread pitch gauge is used across a wide range of industries, from automotive and aerospace to construction and electronics. Let’s look at some specific applications where this tool shines:

1. Automotive Manufacturing

In automotive manufacturing, precision is critical. A small error in thread pitch can compromise the safety and functionality of a vehicle. Mechanics and engineers rely on thread pitch gauges to ensure that bolts and screws fit perfectly, preventing loose connections and reducing the risk of accidents.

2. Aerospace Engineering

In aerospace, components must withstand extreme conditions and intense pressures. Even minor discrepancies in thread pitch can lead to catastrophic failures. The thread pitch gauge is indispensable in this field, as it allows engineers to verify the exact specifications of every threaded part, ensuring the safety and reliability of aircraft components.

3. Machinery and Equipment Fabrication

Heavy machinery and industrial equipment depend on robust, durable connections. Thread pitch gauges help maintain the structural integrity of these machines by ensuring that all threaded parts fit securely. This attention to detail reduces wear and tear on the equipment, enhancing longevity and performance.

4. Electronics and Precision Instruments

In electronics and precision instrument manufacturing, even the smallest error can affect the functionality of a device. Thread pitch gauges are essential for maintaining the tight tolerances required in these fields, allowing engineers to create finely-tuned components that work seamlessly together.

The Role of Thread Pitch Gauges in Quality Control

In any manufacturing process, quality control is paramount. The thread pitch gauge plays a vital role in maintaining high standards by verifying that every threaded component meets exact specifications. By using this tool, engineers can detect any variations in thread pitch early in the production process, allowing them to make adjustments before components are assembled.

In fields like aerospace and automotive manufacturing, where failure is not an option, the thread pitch gauge acts as a safeguard, ensuring that each product meets stringent quality standards.

Why Mastering the Thread Pitch Gauge Is a Valuable Skill

For machinists, engineers, and technicians, proficiency with a thread pitch gauge is a valuable skill. It enables them to quickly assess the characteristics of threaded components, saving time and minimizing errors. This expertise is particularly prized in industries that demand precision, as the ability to identify thread specifications accurately can mean the difference between a successful project and a costly failure.

Learning to use a thread pitch gauge effectively also builds a deeper understanding of how threaded connections work. It allows professionals to approach their projects with confidence, knowing that they can deliver components that meet the highest standards of quality and performance.

Conclusion: The Thread Pitch Gauge – A Small Tool with a Big Impact

The thread pitch gauge may seem unassuming, but its impact on the world of precision engineering is immense. By ensuring that threaded components fit perfectly, it upholds the quality, safety, and reliability of products across countless industries. As a fundamental tool in the engineer’s toolkit, the thread pitch gauge is a testament to the importance of attention to detail in achieving perfection.

So next time you see this humble tool, remember: it’s not just a gauge—it’s a guardian of precision and a silent champion of quality in engineering. In the hands of skilled professionals, the thread pitch gauge helps create products that push the boundaries of what’s possible, one thread at a time.