The torque wrench is an essential tool in mechanics and engineering, ensuring precise fastening of bolts and nuts for optimal performance and safety. Over the years, this tool has transformed the way mechanical work is done, playing a pivotal role in industries such as automotive, aerospace, and manufacturing. But how did this invaluable tool come to be? In this article, we’ll explore the history, usage, and legacy of the torque wrench, from its early days as a vintage device to its modern-day innovations.

The Invention of the Torque Wrench: A Historical Milestone

In 1918, Conrad Bahr, an American engineer, developed the torque wrench to meet the growing need for precision in machinery and engineering. During that period, the complexity of machines was rapidly increasing, making it essential to apply the correct amount of torque to fasteners. Bahr’s invention provided an efficient way to do just that, revolutionizing how mechanical work was performed.

The early torque wrenches were relatively simple mechanical devices, yet they were groundbreaking for their time. These tools allowed mechanics and engineers to apply a specific amount of torque to nuts and bolts, ensuring the structural integrity of everything from engines to bridges. The tool quickly gained traction across various industries, becoming a staple for anyone who needed reliable, consistent results in their mechanical work.

Why the Torque Wrench Was Needed

Why was the torque wrench so crucial in the early 20th century? The answer lies in the increasing complexity of machines and vehicles. With the rise of automobiles, airplanes, and industrial machinery, the need for precise assembly became more critical. Incorrectly tightened bolts could lead to catastrophic failures, causing accidents, injuries, or costly repairs. The torque wrench solved this issue by allowing mechanics to apply the perfect amount of force, ensuring that connections were neither too loose nor too tight.

In industries like aerospace, where the margin for error is slim, the torque wrench became indispensable. Over-tightening a bolt could result in damage to delicate components, while under-tightening could lead to parts loosening over time. The torque wrench allowed engineers to strike the perfect balance, making it an essential tool for ensuring safety and reliability in complex mechanical systems.

How Vintage Torque Wrenches Worked

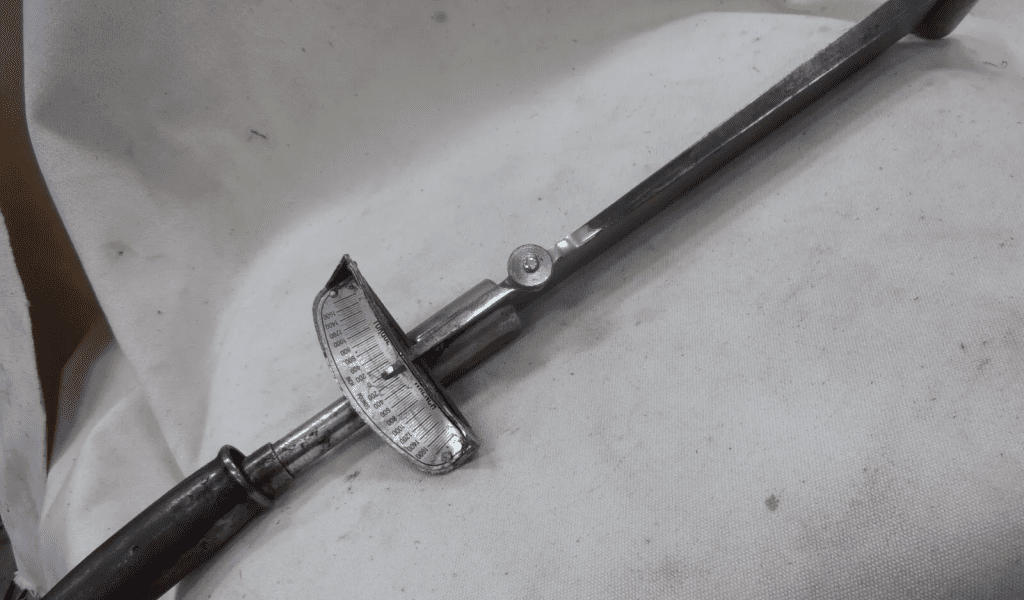

The vintage torque wrenches of the early 20th century were simple yet effective tools. Two main types emerged during this period: the beam-type and the spring-type torque wrench.

- Beam-Type Torque Wrench: This early version featured a beam and pointer system. As the wrench applied torque to a fastener, the beam would bend slightly, causing the pointer to move along a calibrated scale. This allowed the user to read the amount of torque being applied in real-time. Although effective, this type of wrench required the user to maintain constant visual focus on the scale, making it somewhat cumbersome in fast-paced environments.

- Spring-Type Torque Wrench: The spring-type wrench relied on a calibrated spring mechanism to measure torque. As the wrench was turned, the spring would compress, providing resistance proportional to the amount of torque being applied. These wrenches required manual calibration, which could be tricky, but they offered more versatility in various applications.

Both types of vintage torque wrenches had their advantages, but they also came with challenges. They lacked the convenience and accuracy of modern digital wrenches, and users had to rely heavily on manual adjustments and careful attention to detail.

The Evolution of Torque Wrench Technology

While vintage torque wrenches laid the foundation for precision in mechanical work, technological advancements quickly led to the development of more sophisticated versions. Click-type torque wrenches, for instance, emerged as a significant improvement over earlier models. These wrenches use a mechanical click system to signal when the desired torque level is reached, making them more user-friendly and accurate.

Today, digital torque wrenches represent the pinnacle of torque measurement technology. These tools feature electronic displays that show the exact amount of torque being applied, and many models come with built-in memory to store torque settings. Digital wrenches are widely used in industries where accuracy and repeatability are critical, such as aerospace, automotive, and manufacturing.

However, despite these technological advancements, vintage torque wrenches continue to hold a special place in the hearts of mechanics and collectors alike. They represent a simpler time in engineering, when manual skill and craftsmanship played a more significant role in everyday work.

The Importance of Torque Control in Modern Applications

Even though modern torque wrenches are far more advanced than their vintage counterparts, the importance of torque control remains the same. In today’s world, industries rely on torque wrenches to ensure the safety and durability of critical systems. Whether it’s an aircraft engine, a suspension bridge, or a high-performance car, the ability to apply precise torque is crucial to maintaining the integrity of the system.

For example, in automotive repair, over-tightening a bolt can strip the threads or damage sensitive components, while under-tightening can lead to parts vibrating loose over time. Torque wrenches eliminate the guesswork, allowing mechanics to achieve the exact torque required for each fastener. This precision ensures that vehicles remain safe and reliable on the road.

Similarly, in aerospace engineering, torque control is essential to prevent catastrophic failures. Aircraft operate under extreme conditions, and even the smallest mistake in assembly can have dire consequences. Torque wrenches provide engineers with the precision needed to build aircraft that are both safe and high-performing.

The Legacy of the Vintage Torque Wrench

Although modern torque wrenches have largely replaced their vintage predecessors, the legacy of these early tools continues to influence the design and functionality of today’s precision instruments. Enthusiasts and collectors appreciate vintage torque wrenches for their craftsmanship, simplicity, and the role they played in advancing engineering precision.

Collectors often seek out vintage torque wrenches not just for their historical value but also for their usability. Many vintage wrenches, despite their age, are still functional and can be used for basic mechanical tasks. For classic car restorers and vintage machinery enthusiasts, using an original torque wrench adds an authentic touch to the restoration process.

In a world dominated by digital technology, the vintage torque wrench serves as a reminder of the ingenuity and craftsmanship that defined early mechanical engineering. Its legacy lives on in the modern tools we use today, continuing to ensure safety and precision in everything from car engines to skyscrapers.

The Enduring Impact of the Torque Wrench

The torque wrench, invented in 1918, has come a long way since its early days as a simple mechanical device. From the beam and spring designs of vintage models to today’s highly advanced digital tools, the torque wrench has evolved to meet the ever-growing demands of modern engineering and mechanics. Yet, despite these advancements, the core principle remains the same: the need for precise torque control to ensure safety, reliability, and optimal performance.

As we continue to develop new technologies, the vintage torque wrench will always hold a special place in the history of mechanical tools. It represents not only the progress of engineering but also the craftsmanship and attention to detail that defined early 20th-century mechanics. The torque wrench’s legacy endures in the precision tools we use today, continuing to influence the way we approach mechanical work.