The gear puller, a vital tool in mechanics and engineering, has a fascinating history that dates back to the late 19th and early 20th centuries. Developed to solve the challenge of safely removing gears, bearings, and pulleys from shafts and axles, this tool revolutionized mechanical repair and maintenance processes. Before the invention of the gear puller, mechanics had to rely on less efficient and often damaging methods to extract these components. This article explores the history, usage, and legacy of the vintage gear puller, a tool that remains indispensable in workshops today.

Origins of the Gear Puller: Innovation in the Late 19th Century

In the industrial revolution, as machinery became more complex and widespread, mechanics faced new challenges in maintaining and repairing mechanical systems. One of the biggest hurdles was the safe removal of gears and bearings from rotating shafts without damaging the components or surrounding parts. Before gear pullers, removing these parts required brute force or makeshift tools, often leading to irreversible damage.

The introduction of the gear puller offered a breakthrough solution. Developed in the late 19th century, this tool provided a precise, controlled method for pulling gears, bearings, and pulleys from shafts. This invention was especially useful in the automotive and industrial sectors, where the maintenance of mechanical systems became critical to operational efficiency. The gear puller quickly became a staple in workshops, laying the foundation for modern mechanical repair techniques.

How the Gear Puller Works: Precision Meets Simplicity

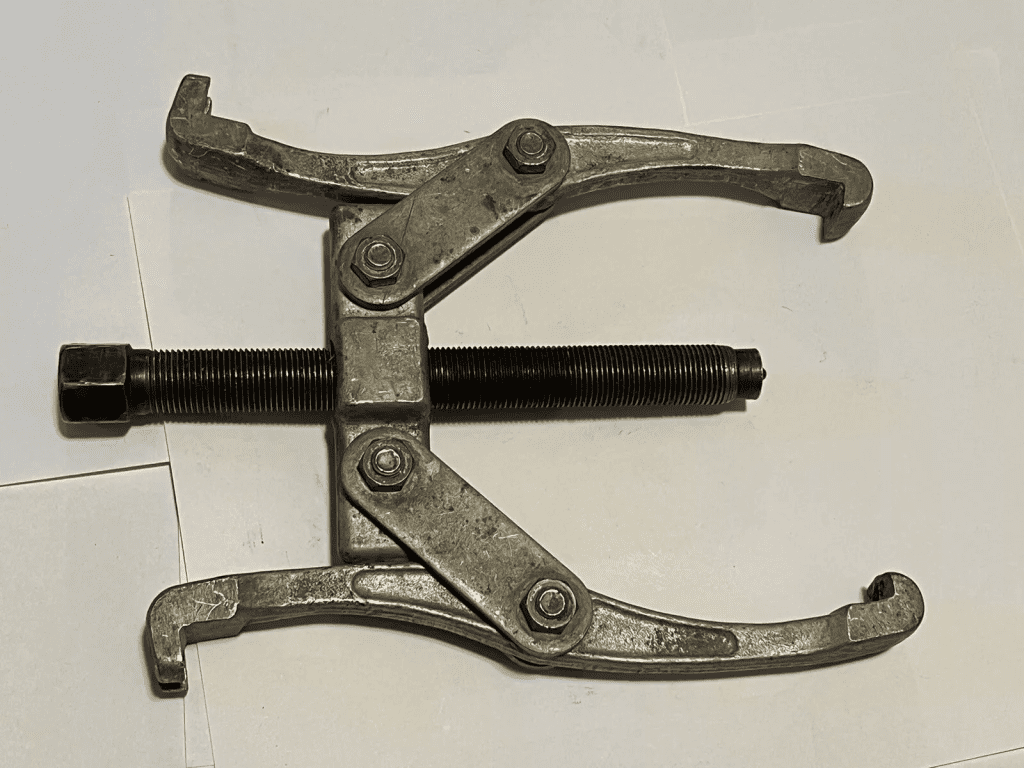

At its core, the gear puller is a simple yet highly effective tool designed to apply controlled force. The standard gear puller consists of a central screw and two or three arms, which grip the part to be removed. Here’s a breakdown of its operation:

- Positioning the Arms: The arms of the gear puller are placed around the gear, bearing, or pulley that needs to be removed. The arms are adjustable to fit various sizes and shapes, making the tool versatile for different applications.

- Tightening the Central Screw: Once the arms are in place, the mechanic tightens the central screw. As the screw turns, it pushes against the shaft while pulling the component off it, applying an even and controlled force.

- Efficient Removal: The gear puller ensures that the component is removed without damaging either the part itself or the surrounding machinery, making it a safer and more efficient alternative to older methods.

Vintage gear pullers were often manually operated, requiring physical force through the screw mechanism. Despite their simplicity, these tools were highly regarded for their precision and reliability, making them invaluable in delicate mechanical operations.

Types of Vintage Gear Pullers: Tools That Shaped the Industry

Over the years, various designs of gear pullers were developed to meet different mechanical needs. Although modern versions may now include hydraulic or pneumatic components for greater ease and efficiency, the vintage gear pullers were marvels of manual engineering. Here are a few types that have left a mark on mechanical history:

- Two-Jaw Gear Puller: Featuring two arms, this type of puller is commonly used for smaller components or when space around the gear is limited. It offers enough grip for small to medium-sized tasks.

- Three-Jaw Gear Puller: The three-jaw puller is ideal for evenly distributing the pulling force around the gear or bearing. It provides more stability and is typically used for larger or more delicate components.

- Slide Hammer Puller: A slide hammer puller uses an impact force to extract parts. Though more aggressive than the screw-based pullers, it was valuable for removing stubborn components that required extra pulling force.

Each of these designs offered unique advantages, but they all shared one key element: they simplified the process of removing parts without causing damage. This innovation not only made mechanical repairs more efficient but also extended the life of expensive components.

The Role of the Gear Puller in Automotive and Industrial Fields

The impact of the gear puller in the automotive and industrial sectors cannot be overstated. In automotive repair, gear pullers were essential tools for working on engines, transmissions, and other critical systems. Mechanics used them to safely remove bearings, gears, and pulleys, allowing for more precise and less damaging repairs.

In industrial settings, where heavy machinery often operated under extreme conditions, the need for maintenance was constant. Gear pullers allowed mechanics to quickly and safely service machinery without the need for expensive replacements or prolonged downtime. This led to greater operational efficiency and longer equipment lifespans.

Legacy of the Vintage Gear Puller: A Testament to Mechanical Ingenuity

The legacy of the vintage gear puller is evident in both its continued use and its influence on modern tool designs. Early gear pullers were crafted with durability and precision, qualities that have made them enduringly popular among both professionals and hobbyists.

Many collectors and enthusiasts prize vintage gear pullers for their mechanical ingenuity and historical significance. These tools are often featured in museums and antique collections as symbols of the innovation that drove the early days of mechanical engineering. The craftsmanship involved in making these tools reflects a time when manual precision was a hallmark of quality.

Despite the advances in technology, the fundamental design of the gear puller remains largely unchanged. Modern versions may incorporate hydraulic or pneumatic systems for added convenience, but the basic principle of controlled force and precision remains intact. The vintage gear puller laid the foundation for this evolution, and its impact on mechanical repair practices continues to be felt today.

Modern Use and Collectibility of Vintage Gear Pullers

While modern gear pullers have become more sophisticated, vintage gear pullers are still appreciated for their craftsmanship and reliability. Many mechanics prefer using these older tools, praising them for their straightforward design and long-lasting performance. In addition, vintage gear pullers have become collectible items, admired for their historical value and the role they played in shaping modern mechanical practices.

For enthusiasts, finding a well-preserved vintage gear puller is akin to discovering a piece of history. These tools, once the backbone of early mechanical repair, now serve as reminders of the innovation and precision that have defined engineering for over a century.

Conclusion: The Enduring Influence of the Gear Puller

The gear puller is a remarkable tool that revolutionized mechanical repair, allowing for safer and more efficient removal of gears, bearings, and pulleys. From its invention in the late 19th century to its continued use today, the gear puller’s legacy is one of innovation, precision, and craftsmanship.

Vintage gear pullers, in particular, stand as enduring symbols of early mechanical ingenuity. While modern versions have evolved, the basic principles remain the same—a testament to the timelessness of a tool that continues to play a vital role in mechanics and engineering. Whether you’re a professional mechanic, an industrial worker, or a collector, the vintage gear puller represents the best of mechanical design, offering both historical significance and practical value.